Applications Industry Sector

Construction of anechoic chambers

An anechoic chamber is an environment structured in such a way as to reduce 'reflection' by its surfaces as much as possible. It is usually realised to simulate, experiment and recreate conditions of 'total absence of acoustic echoes'.

In contrast to traditional solutions, which very often consist of prefabricated products, our constructions are designed and built to measure for each specific case. This is the only way to guarantee truly effective results, since the variables involved are extremely numerous.

The anechoic chambers are therefore designed and built on the basis of construction solutions that allow for high levels of sound insulation between inside and outside, realising conditions of almost absolute silence inside. In addition, in order to reduce acoustic reflections of internal surfaces to a minimum, the walls, ceiling and sometimes even the floor are normally completely covered with highly sound-absorbent materials, with a sharp conformation, to break up and absorb the incident acoustic wave front.

Gas turbine insulation

ITE Isolanti operates in the thermal and acoustic insulation sector, in synergy with the main manufacturers of Gas Turbines to obtain ecologically advanced solutions in instrumentation insulation Our structure makes use of sophisticated automated and numerically controlled systems for the prototyping, design and production of manufactured products, supported by the work of qualified technicians and teams of workers dedicated to surveying measurements and assembly.

The design is carried out using 3D modelling tools starting from one of the following conditions:

- Measurement survey by our team of skilled workers

- Two-dimensional technical drawings of the object

- Shipment by the supplier of the already realised 3D model.

We then proceed to create the drawing with appropriate software to obtain the mathematical 3D CAD model of the gas machine, which accurately defines every part of its shape. Using the obtained model, we proceed to the manufacture of the insulating mattresses, with the aid of an automated process using a sophisticated system of cutting plotters and numerically controlled machines, industrial sewing machines, and various special machines that complete the processing.

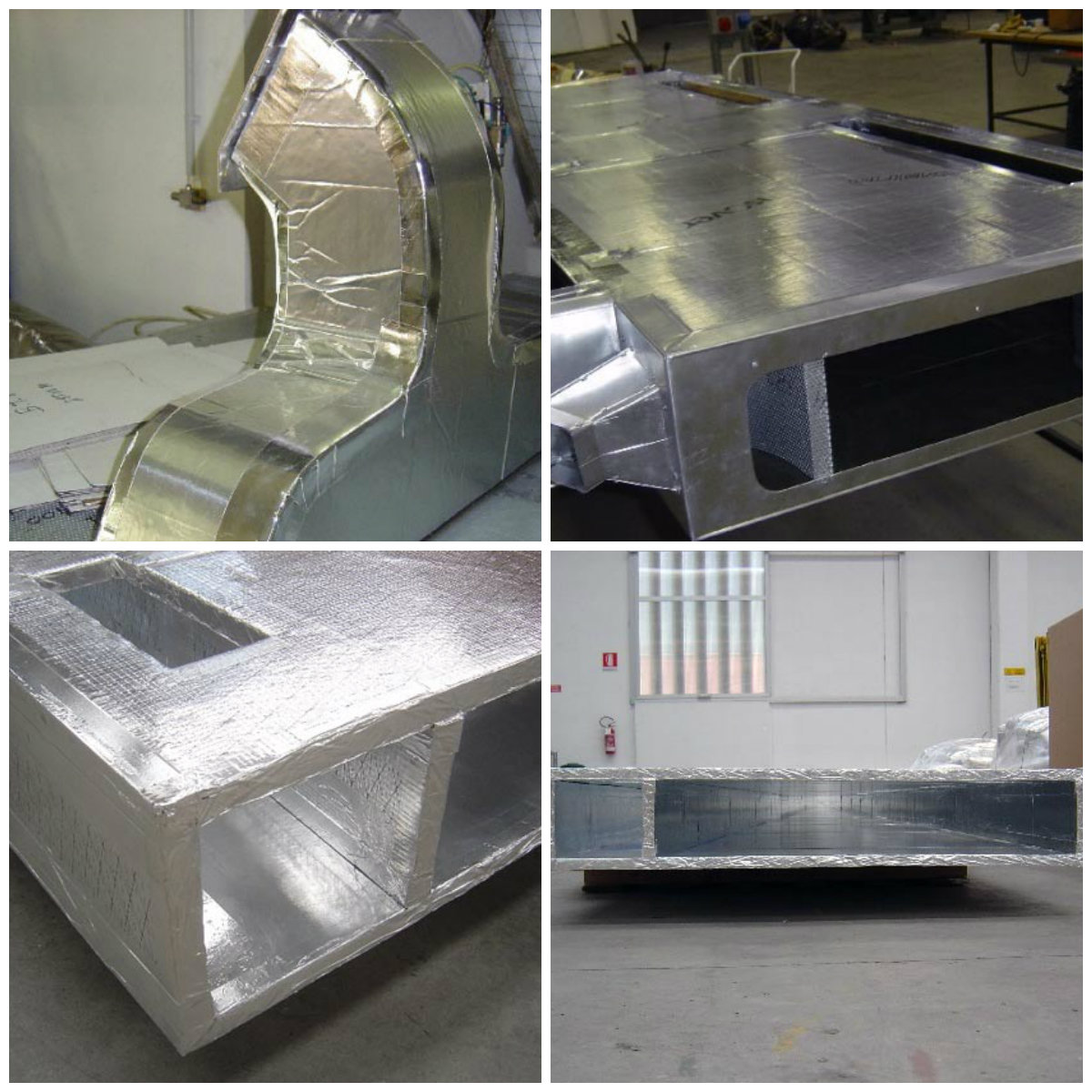

Compressor casing soundproofing

ITE Isolanti works in the field of thermal and acoustic insulation to obtain ecologically advanced solutions in the insulation of equipment Our structure makes use of sophisticated automated and numerically controlled systems for the prototyping, design and production of manufactured products, supported by the work of qualified technicians and teams of workers dedicated to measuring and assembly.

The design is carried out using 3D modelling tools starting from one of the following conditions:

- Measurement survey by our team of skilled workers

- Two-dimensional technical drawings of the object

- Shipment by the supplier of the already realised 3D model.

We then proceed to create the drawing with appropriate software to obtain the mathematical 3D CAD model of the gas machine, which accurately defines every part of its shape. Using the resulting model, we proceed to manufacture the insulating panels, with the aid of an automated process using a sophisticated system of cutting plotters and numerically controlled die-cutting machines, industrial sewing machines, and various special machines that complete the process.

Air ducting soundproofing

Soundproofing forced ventilation systems, air ducts and grilles can bring about an improvement in company conditions.

Air exchange is a necessity for anyone working in an enclosed environment. For this purpose, one is obliged to create a forced ventilation system.

These systems, unfortunately, have the particularity of being very noisy. Our technical staff has created an innovative technology that guarantees efficiency and silence. To silence a ventilation duct, it is necessary to create a silencer inside it, which allows air to pass through, but at the same time does not allow the noise to propagate and amplify.

Ventilation system equipment and the passage of air through ducts can give rise to unwanted noise, even loud noise, which generally has to be attenuated. The noise can also come from an adjacent flat or room along the air ducts, passing through the walls.

Effective noise reduction is an important factor in creating a more pleasant home and work environment. Possible alternatives for noise reduction are the use of quieter ventilation systems, silencers and insulators.

ITE Isolanti products are used in a wide range of ventilation systems and silencers. Ducts function as an acoustic transmission channel that diffuses sound from one room to another. Insulation applied to the outside of the duct helps to attenuate the intensity of sound passing through the duct walls.

Boiler / storage tank insulation

Thermal storage tanks are used for the storage of hot domestic water typically from plate heat exchangers, but not only. They are used for all cases in which it is necessary to have a sufficient supply of hot water ready for use. They are equipped with adequate insulation for thermal insulation, with an external finish that can also be customised.

Thermal power plant and machine room insulation

A well-insulated industrial plant guarantees better efficiency, minimising heat loss and thus reducing energy consumption; furthermore, insulation protects the plant, maximising its lifespan.

A variety of insulation products are used, but by assessing the characteristics of the plant and the customer’s needs, we are able to offer the best solution at the most convenient price. We specialise in the design and installation of hot and cold industrial thermal insulation. Thanks to our experience and technical knowledge, we are able to offer a complete job – from design to installation of the insulation – executed according to the highest standards of Safety, Quality and respect for the Environment, offering the best solutions to limit heat loss, maintain temperatures and maximise process efficiency.

The insulation materials we install are the best on the market and guarantee exceptional thermal performance: mineral or glass fibre materials, polyurethane or phenolic resins, cellular glass, closed cell elastomers, and new generation aerogel materials. The finishes we install range from aluminium to stainless steel and non-metallic coatings. The experience gained and the level of specialisation of our technical design staff and personnel allow us to propose high-performance, tailor-made solutions.